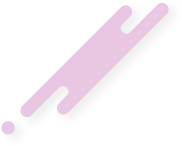

A master tile is used as a color reference across productions to maintain consistency. This ensures that all tile designs align with the same color standard, providing uniformity.

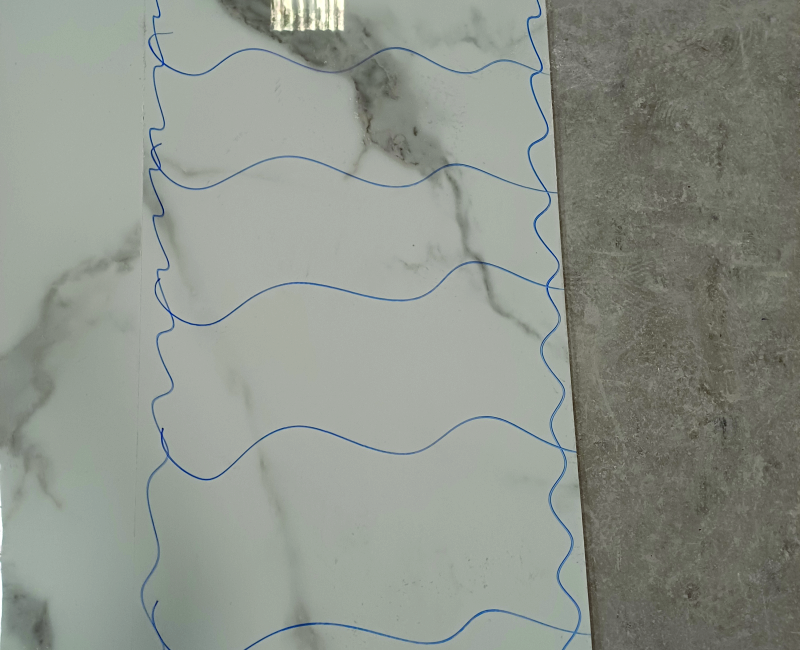

This process ensures tiles have a smooth, even surface without irregularities. Flatness is crucial for proper installation and aesthetics, especially for flooring applications.

Random box checks and floor tests confirm design and color consistency. This visual check ensures the tiles deliver uniform aesthetics when installed.

Thickness inspection is an essential quality control process to ensure tiles meet required standards. Each tile’s thickness is measured to detect deviations and maintain consistency, ensuring the final product.

This inspection checks the shine or reflectiveness of tiles, ensuring they meet desired gloss levels. Consistent gloss enhances visual appeal and ensures the tiles meet aesthetic standards.

Measuring tile dimensions and diagonals ensures they meet size specifications and maintain proper angles. This inspection prevents misshapen tiles and ensures uniformity in the final product.

Measures the tile’s ability to resist moisture, ensuring suitability for wet areas like bathrooms. Tiles with low water absorption rates provide better durability in moisture-prone environments.

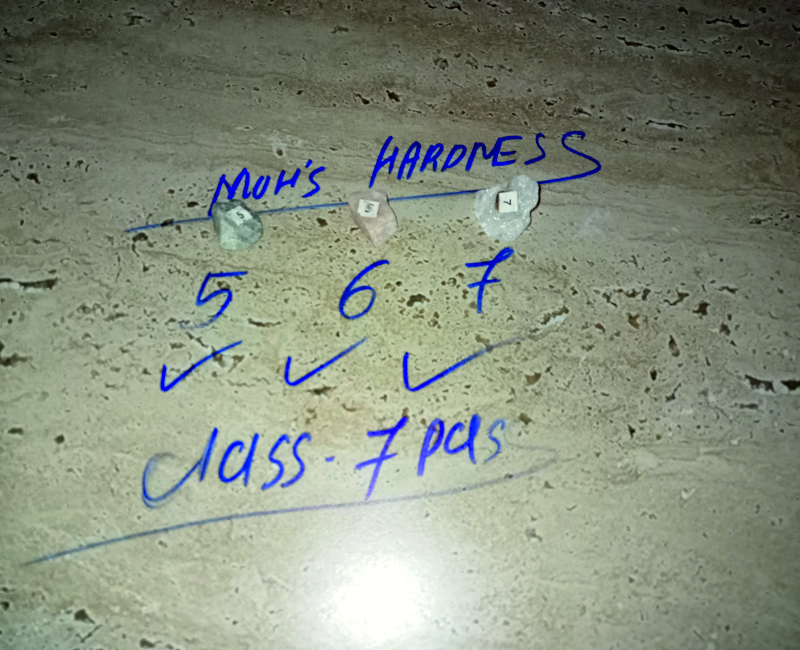

Evaluating surface roughness ensures tiles have the appropriate texture for their intended use. This impacts aesthetics, cleaning ease, and suitability for various environments.

MOR (Modulus of Rupture) testing measures tile strength and durability through bending tests, ensuring they can withstand regular use and stress.

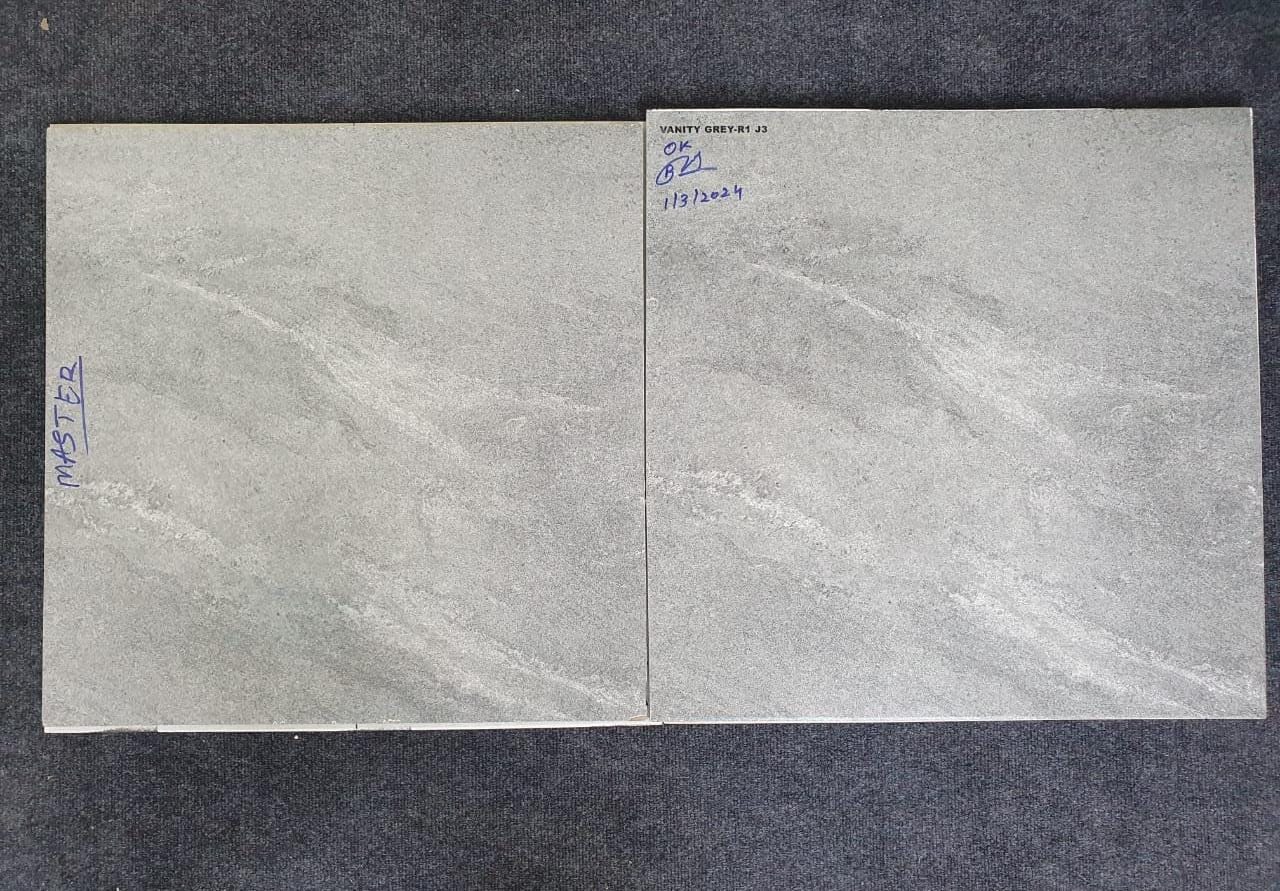

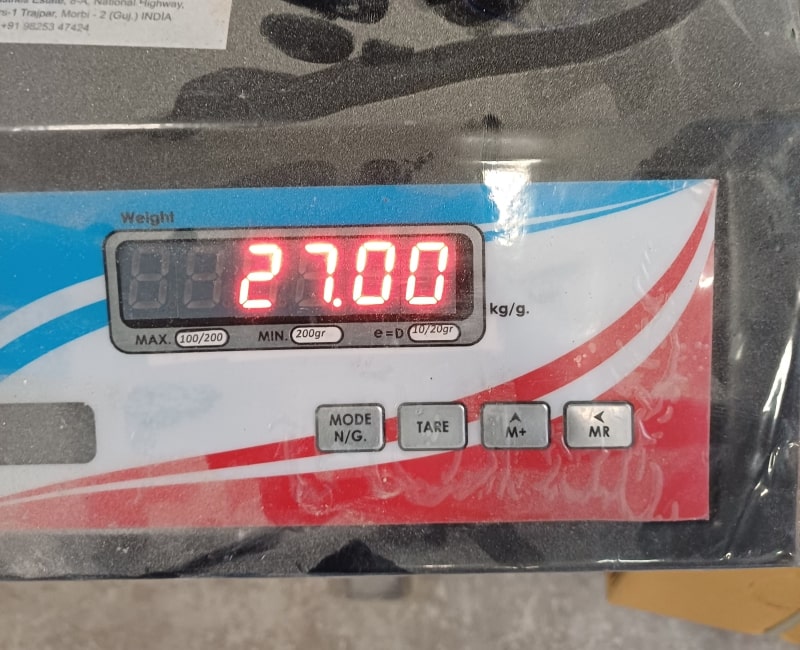

Inspecting box weight confirms accurate packaging by ensuring each box contains the correct tile quantity. It helps maintain consistency throughout the packaging process.

This inspection ensures tiles resist stains and dirt, making them easy to clean and maintain. It ensures convenience and lasting appearance.